Designing for CNC

The key to precise CNC work lies in aligning the physical workpiece with the CAD software to the minimum tolerances.

Registering your part

- Attach the digital model to a physical registration pin/point

- For example, the CNC can be used to make holes that correspond to the form. These can then be registered with pins or secured in place, aligning with fixing points formed into the tool

- Mill a border around the mold so the part can be registered on all sides. This allows for an inlay to be flipped or swapped for double-sided milled parts

- Create a jig through milling

Manufacturing restrictions

- Accessibility. The part might need to be milled from both sides to access the details.

- Be aware of fillets. The drill bit might limit the detail of the cut.

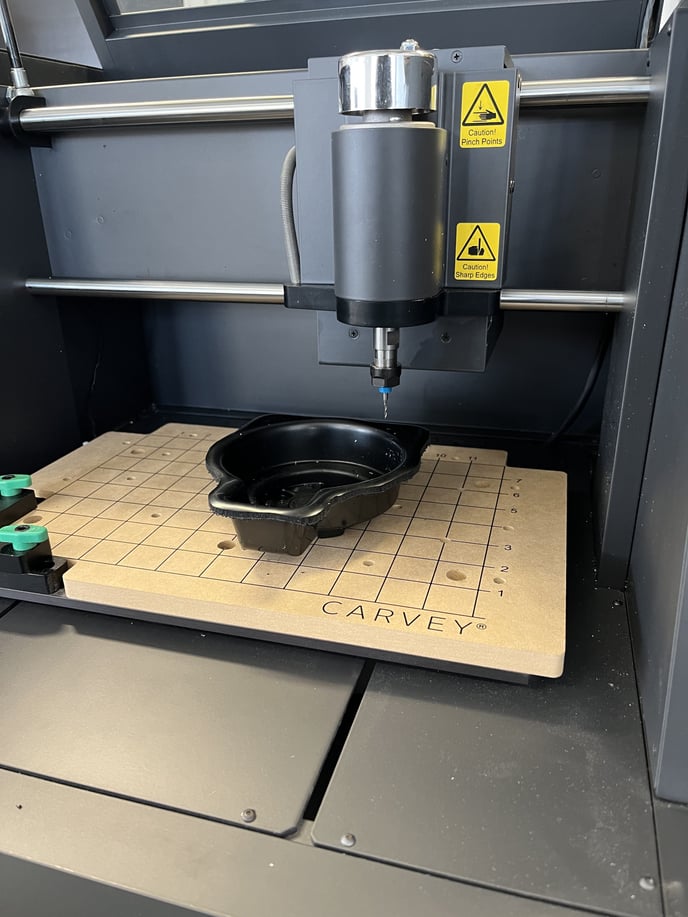

- Methods of attachment. The suction bed of the CNC bed can hold forms in place. If this is not feasible, the tooling can be clamped in place or screwed into the stillage board.

Example

A double-sided ABS part had holes pre-drilled in the form using slotted guides designed into the template. The holes were then pinned into the MDF stillage board at five points where the milling machine had pre-drilled, thereby registering it within CAD.