Error code 41: Temperature rise error

A temperature rise error can occur when the temperature sensor is covered during the heating process.

If the temperature sensor is covered at the beginning of a heating cycle, a warning will now be displayed instead of a temperature rise error.

To prevent this happening, avoid covering the temperature sensor at any time (e.g. with your hands or a tool, as the sensor will not be able to measure the temperature accurately).

To solve the issue, try the following:

- Restart the forming process, ensuring that the sensor is not covered.

If this doesn't solve the issue, run the self test program.

If the problem persists, please contact support@mayku.me

Error code 44: Heater error

Error 44 means that the heaters aren’t getting any power. This could be because:

- The machine has overheated, tripping the temperature failsafe system which cuts power to the heaters

- The switch controlling the heaters is broken (SSR fail)

- The heaters are damaged

If the Mayku Multiplier has performed many cycles and “Error 44” is displayed on the screen:

- Allow the machine to cool

- Restart the machine and check that the machine is running firmware 2.0 or later

Follow these steps to check your machine’s firmware:

If the machine is cold when “Error 44” displays on the screen, it’s likely to be an SSR Fail. Check that the machine is on the latest firmware 2.0. If this does not solve the issue, please contact support@mayku.me who can help you process an RMA return.

Error code 110: Tank draining maintenance

When attempting to perform tank draining maintenance, an error may appear due to an obstructed overpressure valve on the bottom of the machine.

To resolve this issue, try the following:

- Remove any cloths under the machine and run the tank vent again

- Locate the overpressure valve and carefully pull the ring tab. Be prepared for a loud noise and potential water spray, as there might be moisture buildup in the tanks. It's advisable to protect your hands from getting wet during this process.

If the problem persists, please contact support@mayku.me

Error Code 31: Air Tank Leak

In some cases, you might see an air tank leak message when you first power on the Multiplier, especially if the air tanks are completely empty (which can happen during shipping). This usually means that the tanks haven't had enough time to fill up before the error appears.

Suggested fix: After you see the error, simply power cycle the machine. Turn on the Multiplier, wait for the error to show, then turn it off. Give it about 20 seconds, and then turn the machine back on.

If the issue still persists, please don't hesitate to reach out to support@mayku.me for assistance.

Error check fail

This error appears when attempting to update the firmware. It’s typically caused by a Wi-Fi connection that’s too slow to download the update. To resolve the issue, try the following:

- Restart the Multiplier and leave it switched on. The firmware should update automatically in the background, and a small green icon will appear in the top left corner when complete.

- A workaround to overcome a weak Wi-Fi signal is to tether another device, such as a smartphone, to establish an internet connection and proceed with the firmware update. For iPhones, keep the phone on the mobile tethering screen, don't let it sleep or try connecting another device (such as a laptop) to the phone first.

- Please note that connecting a device via USB is not currently supported on the machine. The upcoming introduction of EAP enterprise encryption aims to address these connectivity issues.

Note: Companies that have a public facing network often have tight restrictions so if you are experiencing issues connecting your machine to wifi and/or updating to the latest firmware, it might be worth checking with the technician who manages the company network.

If the problem persists, please contact support@mayku.me

Firmware crash after each form

If the Multiplier firmware crashes during the "hold" stage when making a new mold, this indicates a faulty main board.

Please ensure the machine is on the latest firmware version before you contact support@mayku.me

To check you’re on the latest firmware, do the following:

Select Menu > Firmware > Check for updates on the Mayku Multiplier interface.

Updates are completely silent and will happen automatically as long as your Mayku Multiplier is connected to Wi-Fi.

If this doesn’t resolve the issue, an RMA will need to be processed.

Handle hard to close lid when inserting sheet

The thicker the material, the more force may be needed to help lock the sheet in place when inserting into the machine. You can help aid this by applying downward force on to the handle as you close the lid. This is also true for helping to release the locking ring after forming. Do not worry about being a bit rough with this.

You will notice that once the sheet has been inserted that the vacuum will switch on - this will start sucking the sheet on to the rubber seal, and make closing the handle and locking the sheet a little easier too.

Handle hard to close when forming large parts

The maximum volume of a part that can fit in the Multiplier is 3.5 liters.

Due to the dome shape of the pressure chamber, taller objects will need be narrower and positioned in the centre of the forming bed. If you wish to form objects that are positioned close to the edge of the forming bed, they will need to be shallower in order to prevent them coming into contact with the dome. See images below for a guide on this.

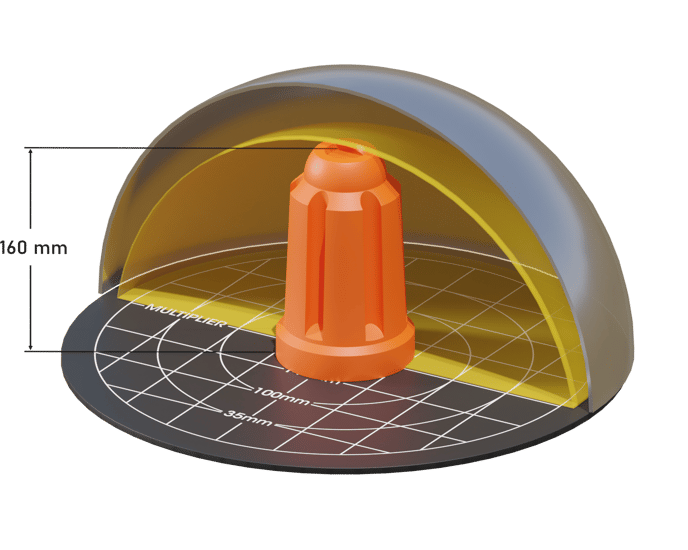

Tall and narrow templates, up to 160mm, can be placed in the centre of the forming bed:

For wider templates, such as in this example, the maximum height allowed is 60mm:

If you wish to utilize the entire forming bed, the template (or templates) must be shallower, as demonstrated in this example:

For large parts to form successfully, we must remove excess air that is in the dome above the heated sheet so that there is enough space for the hot sheet to close over the part and form successfully. If we don’t remove this air, the top lid and handle will be very difficult to close and lock.

You will see two arrows on the screen whilst the sheet is being heated - one "up" arrow and one "down" arrow.

To control how much air is removed from the dome, press the "up" arrow whilst the sheet is being heated. You will notice that instead of remaining level, the heated sheet will start to be pulled upwards towards the heater. This will create more space when the sheet is placed over a large tool and mean that not as much air needs to be removed when you lock the dome in place.

Be careful not to pull too much air from the dome so that the sheet is pulled up into the heaters as this can be dangerous. Always stay by your machine and keep an eye on the sheet as you are using the arrows.

Pressing the down arrow will switch off the vacuum in the dome and let the sheet back down to the horizontal level or further.

The Mayku Multiplier lid isn’t closing and/or there is excessive material drooping:

If the part you are forming is within the recommended parameters and you are experiencing difficulties closing the lid it could be due to dirty seals, outdated firmware or a faulty vacuum pump.

Dirty seals

Dirt and debris on the seal can cause material to droop, which makes it hard to level the sheet an close the lid. To clean the seal, use a damp microfiber cloth and gently wipe it in a circular motion. Ensure that the seal is properly positioned in the dome. We recommend cleaning the seal on a weekly basis.

For a deep clean, use IPA and a microfiber cloth and gently wipe it in a circular motion.

Outdated firmware

Check your Mayku Multiplier has been updated to the latest firmware.

To update your Mayku Multiplier firmware, navigate to: Menu > Firmware > Check for updates

Your Mayku Multiplier will update automatically if you’re connected to Wi-Fi. Updates are completely silent. If updating the firmware doesn’t solve the issue and if there is excessive sheet drooping, this may indicate a fault with the vacuum pump - please contact support@mayku.me

Multiplier Lid Closing whilst heating the sheet

Check that your Mayku Multiplier has been updated to the latest firmware 2.0.2

To update your Mayku Multiplier firmware, connect to wifi and navigate to:

Menu > Firmware > Check for updates

- Set the pre-charged pressure in menu > settings

(Depending on what material you are using, set the pre-charge pressure to 45psi for HIPS, PETG & EVA / 50psi for ABS / 60psi for PMMA & UHMW)

The pressurising will happen after the material is loaded but before you open the lid. In previous firmwares, the pressurising and heating happened when the lid was open and the vibration from the compressor caused the lid to partly close.

- Pressurise with lid down - yes

If the lid still closes then use a hairdryer and warm up the pistons for 30 seconds each. You only have to do this at the beginning of the day/each session

If neither work, a piston replacement is required.

Lid sensor Fail

The Multiplier home screen indicates that the lid must be opened prior to initiating the thermoforming process, despite the lid already being in a fully open position.

1. Locate the limit switch at the back of the Multiplier

2. Partially open the Multiplier lid and feel if the limit switch is straight or bent.

3. If the limit switch is straight, as shown in the image below, gently bend it at the base. Just be cautious not to apply too much pressure to avoid it breaking.

Forms sticking to seal

Sometimes, after forming a part, the sheet can stay stuck to the seal at the top of the machine. If it does not fall off after a few seconds, use a flat head screwdriver or any hard flat object to pry the sheet from the seal and it should fall away easily.

Cooling

Different materials have different heating times which affects how many forms you can do in one session. When the Multiplier dome reaches between 110 - 125 °C "Heater Error 44" is displayed on screen. This means that the machine needs to cool down to 30 °C before you can start your forming cycle again.

The cooling down process of the dome can be sped up by using a fan with a piece of cardboard positioned so that the cool air deflects into the dome as per attached screenshot. Alternatively, you can use an air gun attachment, and blast cold air into the dome area of the machine.

New forms can continue once the dome cools - check the metrics by holding down on the home screen.

Purple bleed across the screen

A purple bleed on the screen indicates physical damage to the screen during shipping or while in use. Please contact Customer Support who will be able to help you further.

Other reasons for failed forms

For good results, avoid inserting the tool too early. Doing this can disrupt the temperature sensor's readings and result in the sheet being pulled into the dome.