To maintain your Multiplier in optimal condition, we suggest following the maintenance schedule below. This schedule assumes a usage frequency of 2,500 forming cycles per year.

Tip: If the usage frequency is higher, we recommend more frequent maintenance to ensure optimal forming results.

Weekly tasks:

Cleaning the seal

The Multiplier has a rubber seal that keeps the pressurized air inside the dome when creating a form. The seal can be found on the inside rim of the forming chamber. It is important to keep the seal clean and clear of any debris as even a small amount can create a gap. If a gap is created, an airtight seal cannot be formed, causing the sheet material to droop and making it hard to close the lid. If this happens, clean the seals well and try another form.

To clean the seal, use a damp microfiber cloth and gently wipe it in a circular motion. Ensure that the seal is properly secured to the dome, an airtight seal is essential for optimal performance. Wipe away any excess moisture with a clean microfiber cloth.

Recommended deep clean frequency every 40 cycles or weekly, depending on user frequency. A maintenance alert will appear on screen when it’s time to clean the seal. For the deep clean, we recommend using IPA and a microfibre cloth.

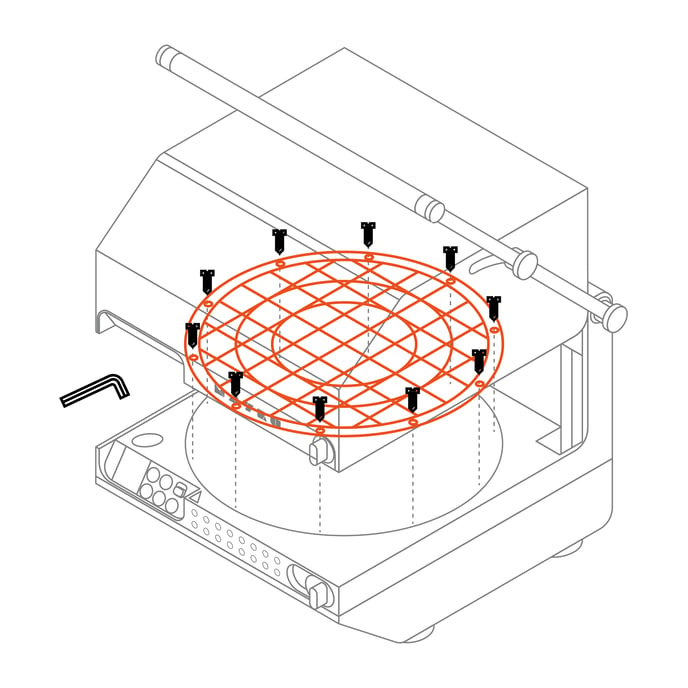

Cleaning the baseplate

Cleaning the baseplate

Equipment:

- Torx head Allen key

- Microfiber cloth

- Isopropyl alcohol

To clean the baseplate, follow these steps:

- Locate the screws holding the baseplate in place.

- Unscrew the screws with an Allen key to remove the baseplate.

- Clean the baseplate using a microfiber cloth and some isopropyl alcohol , removing any dirt or debris.

- Once cleaned and dry, reattach the baseplate by screwing it back into place.

Make sure to handle the screws carefully and avoid over tightening them when reattaching the baseplate. This process will help maintain the performance of the Mayku Multiplier.

Recommended cleaning frequency every 70 cycles or weekly, depending on user frequency. A maintenance alert will appear on screen when it’s time to clean the baseplate.

![]() Check heaters for signs of cracking or failure

Check heaters for signs of cracking or failure

The heaters are located inside and at the top of the dome. A flashlight is recommended to view properly.

Open the lid of the Multiplier, and look up into the dome with a flashlight to inspect.

Do not attempt to fix any cracks. If any cracks are present please contact support@mayku.me.

Monthly tasks:

Tank draining

Regular tank draining is recommended to prevent moisture buildup and rust. The tanks are made from stainless steel and are rust-resistant, but if not drained regularly, moisture can accumulate and end up in the multiplier dome.

Recommended cleaning frequency = 100 cycles of monthly depending on user frequency.

A maintenance alert will appear on the screen when it's time to drain the tanks, providing step-by-step instructions.

Moisture will be released below the valve so keep the area clear or place a tray to catch the moisture deposit. This is a loud release so remember to use protective goggles and ear defenders.

Equipment:

- Noise protection (ear defenders)

- Eye protection

You can also drain the tanks without waiting for a maintenance alert to appear on screen. Here you have two options:

To activate tank draining via the control panel:

- Navigate to the main menu and select Maintenance

- Activate the tank draining process as directed on screen

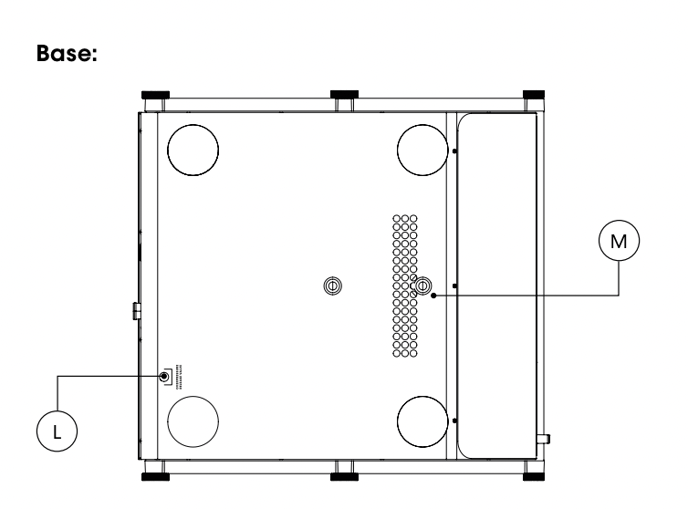

To manually drain the tank:

- Locate the overpressure valve and pull the ring tab (M) in a downwards direction. Using a pencil can be useful here to help trigger the valve. This action will initiate the drainage process. Please be aware that pulling the ring tab will result in a loud noise and your hands may get wet due to water release.

Please exercise caution while performing manual tank draining and ensure that you are prepared for the noise and potential water spray.

Cleaning the heat sensor

Equipment:

- Air gun

- Cotton swab

To clean the heat sensor, follow these steps:

- Use dry compressed air to blow away any debris or obstructions that may be present on the heat sensor. This will help ensure accurate temperature readings and optimal performance

- If there are any stubborn residues or dirt on the heat sensor, you can use a cotton swab. Gently rub the cotton swab over the sensor to clean it, being careful not to apply excessive force

By regularly cleaning the heat sensor, you can maintain its functionality and ensure accurate temperature measurements during operation.

Cleaning the heat reflector

The heat reflector is located inside and at the top of the dome. A flashlight is recommended to view properly. Recommended cleaning frequency every 30 cycles of monthly depending on user frequency.

Open the lid of the Multiplier, and look up into the dome with a flashlight to inspect. Excess buildup of plastic dust or residue on the heaters will look cloudy/white if present, and should be cleaned immediately.

Equipment:

- Flashlight

- Microfiber cloth

- Isopropyl alcohol

To clean the heat reflector in the Mayku Multiplier, follow these steps:

- Ensure the lamp is cold and safe to touch by leaving the machine idle prior to cleaning

- Use a microfiber cloth and some isopropyl alcohol to gently clean the reflector surface. The soft and lint-free nature of a microfiber cloth will help prevent scratches or damage to the reflector

- When cleaning, take care to avoid the heaters. Direct contact with the heaters can cause damage or affect their performance

It's recommended to keep the Multiplier lid closed when not in use to keep out dust.

By regularly cleaning the heat reflector with a microfiber cloth, you can maintain its cleanliness and ensure efficient heat distribution during the forming process.

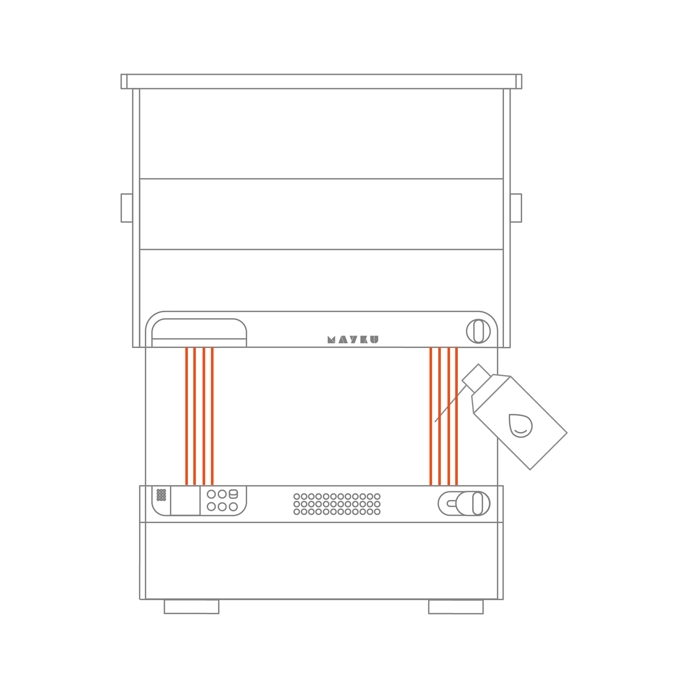

Lubricating the rails

Lubricating the rails

If you notice that the rails of the Mayku Multiplier are running dry and producing a grating sound, it may be necessary to lubricate them. Here are the recommended steps for lubricating the rails:

- Use a microfiber cloth to ensure that the rails are clean and free from any debris or dirt and move the lid up and down a few times.

- Apply a small amount of lithium-based lubricant specifically designed for this purpose to the rails. This lubricant will help reduce friction and eliminate the grating sound.

Important: Avoid using any dry lubricants such as PTFE powder or graphite powder with recirculating ball or roller bearings. While these lubricants are suitable for sliding motion, they provide limited benefits for rolling friction. We recommend Loctite Synthetic Grease SuperLUBE tube.

By appropriately lubricating the rails with a lithium-based lubricant, you can ensure smooth movement and optimal performance of the Mayku Multiplier during operation.