What is vacuum forming?

Vacuum forming is the oldest method of thermoforming, and refers to the use of a vacuum to remove the air between heated plastic material and a template. The subsequent vacuum causes the plastic material to fully conform to a template, capturing details, shape, and other features.

First, a plastic material, typically in the form of a sheet or a roll, is loaded onto the vacuum machine’s material carrier, where it is heated from above.

Once sufficiently softened, the vacuum-forming tool is pulled closer to the template, creating a seal. After this, a vacuum pump creates a vacuum, drawing the sheet over the template in the vacuum-forming tool.

The resultant plastic cools and sets, then is removed by hand or with the use of air. If necessary, it can then be trimmed or otherwise modified to meet certain specifications.

Stages of the vacuum forming process

The vacuum forming process consists of the following main stages.

- Template design and manufacturing

- Vacuum forming machine set up

- Heating the plastic

- Applying the vacuum to the heated plastic

- Cooldown and finishing process

Templates used for vacuum forming

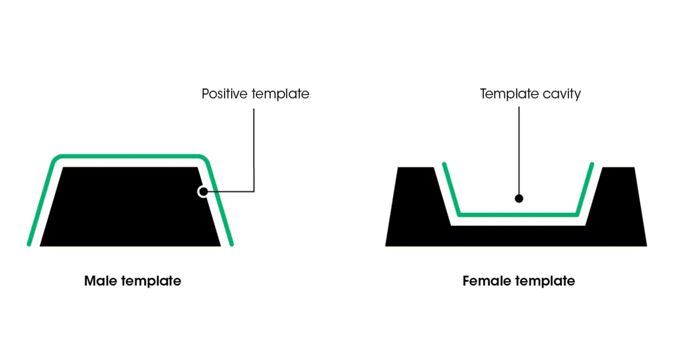

During the vacuum forming process, tools called templates are used to create molds or parts and tools. These templates can be male (also referred to as “positive”) or female (“negative”).

A male template is convex. When a heated plastic sheet is placed on it, the male template will help form the inner dimensions of the object. A female template meanwhile is concave, guaranteeing dimensional accuracy on the exterior of the part created, because the plastic sheet is formed inside the template.

In vacuum forming, male templates are more common, as the materials used are typically thinner, and the level of detail expected on applications such as packaging is not as high.

The benefits of vacuum forming

Vacuum forming offers manufacturers and end users a wide range of benefits. Among them:

- Affordability. For small production runs, vacuum forming is often less costly than processes such as injection molding. This is because vacuum forming tools are easy and affordable to purchase.

- Speed. The vacuum forming process – including design, template manufacturing, and prototyping – is often faster than manufacturing methods, such as injection molding.

- Flexibility. As it is cheaper and faster, vacuum forming providers manufacturers and designers with the ability to test and iterate with prototypes.

- Consistency. Because vacuum forming creates objects with a mold, there is very little variation between individual parts.

- Toughness and durability. While toughness and durability will of course vary depending on the material used, plastic is generally known for its ability to last.

- Food-safe materials. Because it can be used with plastics that are able to be sterilized, vacuum forming is a viable candidate for the creation of food-safe containers.

Vacuum forming limitations

Vacuum forming is a great choice for the creation of parts, tools, or objects that have thin and consistent walls. Other types of thermoforming, such as pressure forming, are better suited to thicker objects, varying wall thickness, or objects that require higher levels of detail.

It is also important to remember several design principles when creating vacuum formed parts. For example, overhangs should be avoided, as they will prevent you from being able to remove your object when it is finished. If you’d like to read more about the design principles of vacuum forming, you can read our guide on tool design and creation.

What is vacuum forming used for

Below are a few of the most common applications that can be made with a vacuum forming machine.

- Packaging. Consumer products that are packaged in plastic are often the result of vacuum forming – as are in-store displays and end caps.

- Industrial goods. Such as crates and containers used to hold tools and or other heavy equipment.

- Signage. Because vacuum-formed materials can often withstand heat, the technology is used to create signs that can be lit from within – like those you would see on a shopfront.

- Automotive and agricultural vehicle parts. Including floor mats, covers, truck beds, and interior components.

- Household items and appliances. Plastic bathtubs, dining utensils – anything plastic and contoured has the potential to be created with vacuum forming.

Types of plastic used for vacuum forming

Another benefit of vacuum forming is its ability to be used with a wide variety of materials that offer different mechanical properties. A few of the materials used in vacuum forming include:

- PETG. Exhibiting good hardness, chemical resistance, impact resistance, transparency and ductility make PETG a good candidate for food-grade tools or parts. It’s also a material offered by Mayku.

- HIPS. Stable, low cost, and impact resistant qualities make HIPS well-suited to thermoforming – and is one of the materials offered by Mayku for our 3D formers.

- EVA. Another material offered by Mayku, with low-temperature toughness and UV resistance.

- Acrylic (PMMA). Transparent and with high impact and chemical resistance, acrylic is often used for protective equipment such as draft shields.

- UHMW. Incredibly durable and resilient form of polyethylene. Resistant to wear and tear and can outperform traditional steel components in some cases.

- ABS. Common material known for strength, impact and heat resistance, and rigidity.

- PC. Durable, UV-resistant, and lightweight, PC is an excellent material choice for machinery parts and lighting fixtures, such as skylights.

- PP. PP is a popular thermoforming material due to its desirable characteristics, such as heat, chemical, and fatigue resistance, as well as its cost-effectiveness.

- LDPE. LDPE is a chemical-resistant material with high strength and slight flexibility.

- HDPE. HDPE offers similar properties as LDPE, but it has increased density and more resistance to stress cracking.

- Cellulose acetate butyrate. Tougher than cellulose acetate, with low moisture absorption, with good transparency and weathering resistance. Can be used to coat metal and wood – or to create steering wheels, blister packaging, or pens.

- Cellulose acetate. Easy to use, highly durable, and flexible. Often used to create eyeglasses.

- PVC. Chemical-resistant, strong, rigid, and flame-retardant properties.

- Polystyrene. Stable, a great insulator, water-resistant, and lightweight, polystyrene is a solid choice for industrial construction and consumer goods.

Learn more about what types of plastic is used for vacuum forming in our guide "Understanding thermoformable materials".

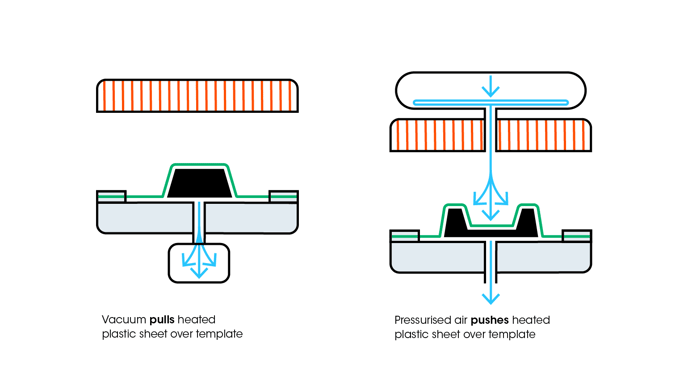

Vacuum forming vs. pressure forming

Vacuum forming is similar to pressure forming, but whereas vacuum forming uses a vacuum, the process of pressure forming applies high amounts of pressure to a plastic sheet that has been placed in or on a template. Because pressure levels are much higher than in vacuum forming, users can leverage pressure forming to achieve higher levels of detail in the parts or tools they create.

Mayku FormBox: Desktop vacuum 3D forming machine

The Mayku FormBox is a compact, vacuum-powered 3D former – and is part of Mayku’s 3D former family. A 3D former is powered by technologies such as thermoforming, and is as easy to use as a desktop 3D printer.

The Mayku FormBox is compatible with multiple materials, including those which are flexible and resin-resistant. It uses a 1000W ceramic heater to heat a plastic forming sheet that can be molded onto a template object. Once the sheet has been heated and lowered onto the template, suction forces the heated sheet into every detail of your part, tool, or object.